Choosing the right end mill could be a really hard thing.

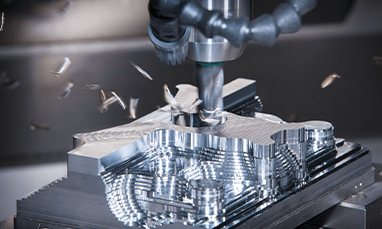

CNC Milling is the procedure of using cutters to remove material by feeding it onto a workpiece. Although it is one of the most ordinary methods for machining parts to meet the precise tolerance, the selection of cutters can be complex.

Fengyan cutter is a mill cutter specialist, manufacturing end mills and other cutting tools and accessories from China.

An end mill is a common cutting tool fitted on a CNC machine.

It is often used in a lathe or machining center for shaping metal or other hard non-metallic materials using rotary cutting action.

There are many types of milling cutters and the type of cutter should correspond to the material being milled, speeds, and feeds.

Check out our tips on how to choose the right end mill.

What Should Consider When Choosing End Mills

An end mill is a cutting tool used for industrial milling. It differs from a drill in application, geometry, and manufacturing. Drills can only cut in the axial direction, while most milling bits can cut in the radial direction.

Not all cutters can cut axially; only those that are designed to cut axially are called end mills.

When preparing for the making process, you may encounter questions about which type should be adopted for your CNC machine.

There are several key factors you should take into consideration:

- The parameter feature of end mills

- The shape and type of end mills

- The material of end mills

Now we will introduce the fundamentals of end mill science.