Structural Relief Angle

The angle between the flank face of an integral tool and a reference plane, considering the overall tool structure. It is designed to ensure adequate clearance behind the cutting edge and maintain structural strength.

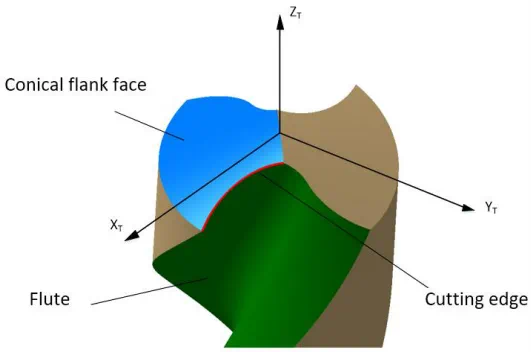

Cutting Edge

The sharp edge of a cutting tool formed by the intersection of the rake face and flank face, which directly engages with and removes material from the workpiece.

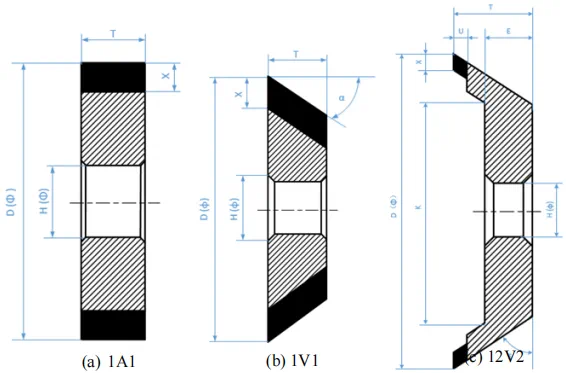

Grinding Wheel

A rotating tool composed of abrasive grains and bonding agents, specifically used for precision form grinding of drill geometry.

CAD/CAM

Computer-Aided Design/Manufacturing

An integrated technological system utilizing computer software for product geometric design and CNC machining path planning.

CNC Grinding Machine

Computer Numerically Controlled grinding machine

A high-precision grinding equipment controlled by computer numerical systems, enabling reproducible processing of complex drill geometric parameters.

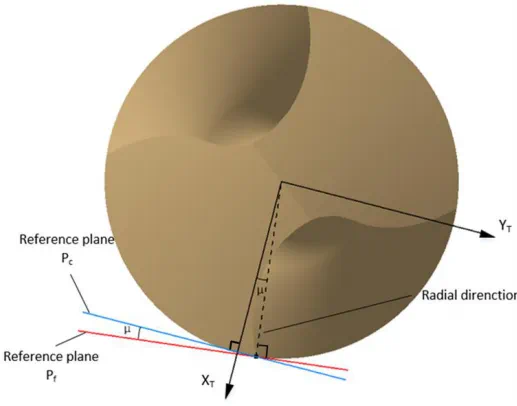

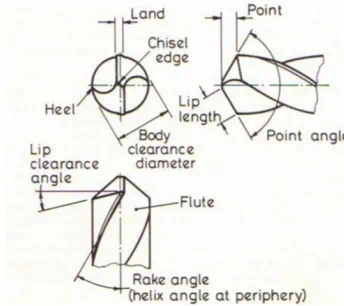

Rake Angle

The angle between the rake face and a plane perpendicular to the cutting direction, influencing chip formation and cutting force magnitude.

Relief Angle

The angle between the flank face and the cutting direction, preventing interference between the flank and workpiece while reducing frictional heat generation.

Thrust Force

The feed force acting axially along the drill bit onto the workpiece during drilling, affecting machine power consumption and hole machining quality.

Torque

The torsional moment required to drive the drill rotation, closely related to cutting resistance, material hardness, and tool geometry.

Chip Evacuation

The process of continuously removing generated chips from the hole through helical flutes and coolant, preventing clogging and overheating.

Helix Angle

The angle between the helical flute and the drill axis, determining chip removal efficiency and drill rigidity.

Web

The solid central core connecting two helical flutes in a drill bit, whose thickness affects drill strength and chisel edge geometry.

Margin

A narrow cylindrical or slightly tapered band along the outer edge of the main cutting edge, functioning to maintain hole diameter, reduce friction, and guide the drill.

Web Thickness

The minimum thickness of the solid central core of a drill bit measured perpendicular to the axis, which determines chisel edge length and overall drill rigidity.

Web Thinning

A grinding process that reduces web thickness to decrease chisel edge length and axial thrust force.

Chisel Edge

The non-cutting transitional region at the drill center formed by the intersection of two flank surfaces. While responsible for initial centering, it generates significant axial thrust.

Chisel Edge Thinning

A specialized grinding process applied to the chisel edge to reduce its length, thereby decreasing centering resistance and axial thrust force.

Primary Cutting Edge

The cutting edge positioned along the leading edges of the drill’s primary flutes, which undertakes the principal material removal during drilling operations.

Secondary Cutting Edge

An auxiliary cutting edge situated behind the primary cutting edge (e.g., in double-margin drills), participating in hole wall finishing and residual material removal.

Land

The solid surface area between the cutting edge and the flute, serving to enhance edge strength and provide a heat dissipation path.

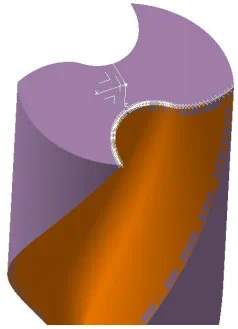

Flute

Helical or straight grooves machined into the drill body to accommodate and evacuate chips, while simultaneously allowing the introduction of cutting fluid.

Flute Length

The effective axial length of the flute along the drill axis, determining maximum drilling depth and chip evacuation capacity.

Neck

A transitional section with slightly reduced diameter behind the cutting edges, providing additional clearance for deeper holes or avoiding clamping interference.

Shank

The cylindrical or tapered rear portion of the drill used for clamping and torque transmission, requiring compatibility with machine tool interfaces.

Coolant Hole

Internal channels running through the drill body to deliver high-pressure coolant directly to the cutting zone for cooling and chip removal.

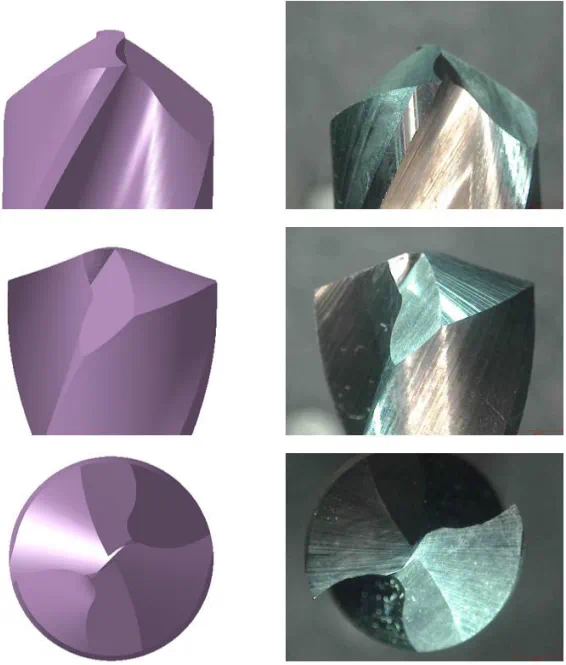

Multi-Facet Point

A drill point geometry featuring additional ground facets beyond the conventional conical shape, improving centering capability and cutting force distribution.

Split Point

A point geometry with notches or eccentric grooves ground into the chisel edge area, enabling chip segmentation and reducing axial thrust.

Self-Centering Point

Specialized geometry (e.g., S-shape, four-facet) designed to maintain hole position accuracy without requiring pre-centering drills.

Step Drill

A composite drill with two or more diameter sections, enabling multi-diameter machining in a single feeding operation.

Indexable Insert Drill

A modular drill system using replaceable carbide inserts mounted on a steel body, reducing tooling costs through insert indexing.

Subland Drill

A drill body incorporating multiple cutting edges with different diameters or geometries for combined operations.

TiAlN Coating

Titanium Aluminum Nitride PVD coating featuring high hardness and thermal resistance, significantly extending tool life in high-temperature applications.

DLC Coating

Diamond-Like Carbon coating characterized by low friction coefficient, preventing material adhesion and built-up edge formation, particularly suitable for non-ferrous materials.

Tool Life

The cumulative machining time or number of holes produced from initial cut until reaching predetermined wear criteria or failure.

Wear Land

A uniformly worn flat area on the flank surface, whose width serves as the primary criterion for tool wear evaluation.

Built-Up Edge (BUE)

Workpiece material adhering to the cutting edge during machining, forming an unstable secondary edge that compromises hole quality and tool integrity.

Chip Load

The thickness of material removed per cutting edge per revolution, serving as a critical parameter for cutting force calculation and feed rate determination.

Surface Roughness (Ra)

Quantitative measure of microscopic irregularities on machined surface, influenced by edge preparation, cutting parameters, and vibrational stability.

Runout

The radial deviation of cutting edges from the drill axis during rotation, adversely affecting hole accuracy and tool longevity.

Tool Deflection

Elastic bending of the drill under cutting forces, causing hole position deviation and diameter enlargement.

Micro-Drill

Typically sub-3mm diameter drills made of HSS or carbide, designed for micro-hole machining with high rotational accuracy.

Deep-Hole Drill

Specialized drills with length-to-diameter ratios exceeding 5:1, featuring internal coolant channels and segmented cutting edges to ensure straightness and efficient chip evacuation in deep drilling applications.